Textile Waste Reduction: 2025 Guide for US Businesses

Anúncios

Implementing effective strategies for textile waste reduction in US businesses by 2025 is crucial for environmental stewardship and financial sustainability, driving innovation in material management and resource efficiency.

Anúncios

Understanding the Textile Waste Crisis in the US

The burgeoning issue of textile waste in the United States has reached a critical juncture, demanding immediate and innovative solutions from businesses across the industry. Each year, millions of tons of textiles end up in landfills, contributing significantly to environmental degradation and resource depletion. This section delves into the scope of the problem, setting the stage for understanding why proactive measures, particularly in textile waste reduction, are not just environmentally responsible but also economically imperative for US businesses.

The sheer volume of discarded clothing, accessories, and home textiles presents a monumental challenge. Fast fashion cycles, coupled with consumer habits, exacerbate this problem, leading to a continuous influx of materials that often have a short lifespan. Addressing this crisis requires a multi-faceted approach, starting with a clear understanding of its origins and impacts.

The Environmental and Economic Toll

The environmental consequences of textile waste are far-reaching. Landfilling textiles leads to methane emissions, a potent greenhouse gas, as organic materials decompose. Synthetic fibers, on the other hand, can take hundreds of years to break down, releasing microplastics into the soil and water. Beyond pollution, the production of new textiles consumes vast amounts of water, energy, and chemicals, further straining natural resources.

Anúncios

- Resource Depletion: High demand for virgin materials like cotton and polyester depletes natural resources and increases energy consumption.

- Pollution: Dyes and chemicals used in textile production contaminate waterways, impacting ecosystems and human health.

- Landfill Burden: Textiles occupy significant landfill space, contributing to greenhouse gas emissions from decomposition.

Economically, the disposal of textile waste represents a lost opportunity. Valuable materials are discarded instead of being reintegrated into the production cycle, leading to increased costs for raw materials and waste management. Businesses that fail to address this issue risk reputational damage, consumer backlash, and potential regulatory penalties in an increasingly sustainability-conscious market. This dual impact underscores the urgency for US businesses to adopt effective textile waste reduction strategies.

In conclusion, the textile waste crisis is a complex challenge with profound environmental and economic implications. Recognizing the scale of this problem is the first step towards developing and implementing effective solutions that foster sustainability and resilience within the US textile industry.

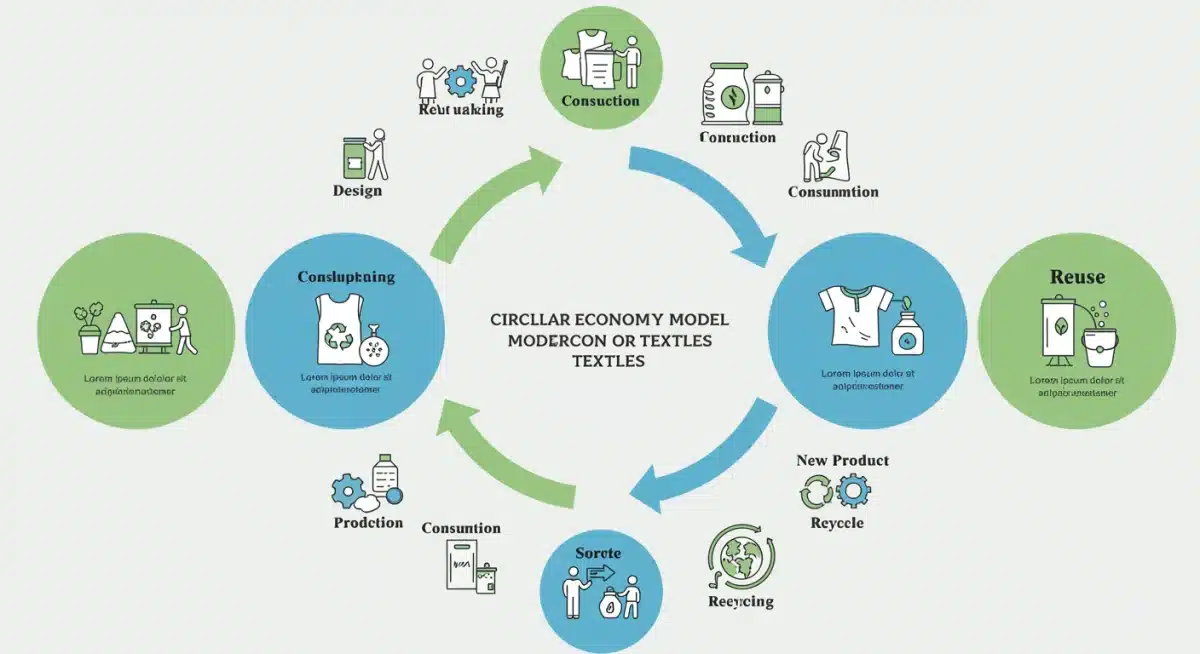

Strategy 1: Embracing Circular Design Principles

One of the most impactful strategies for textile waste reduction begins long before a product reaches the consumer: through circular design. This approach fundamentally shifts how products are conceived, moving away from the traditional linear ‘take-make-dispose’ model towards a system where materials are kept in use for as long as possible. For US businesses, integrating circular design principles is not merely an environmental choice but a strategic business advantage, fostering innovation and reducing long-term costs.

Circular design emphasizes durability, repairability, and recyclability from the outset. It involves selecting materials that are inherently sustainable, designing products that can be easily disassembled, and planning for end-of-life solutions like recycling or composting. This holistic perspective ensures that every component of a textile product is considered for its entire lifecycle, minimizing waste at every stage.

Designing for Durability and Longevity

A cornerstone of circular design is creating products that last. This involves choosing high-quality, resilient materials and employing robust construction techniques. Durable goods reduce the frequency of replacement, directly curtailing waste generation. Brands that invest in longevity can build a reputation for quality and sustainability, appealing to a growing segment of environmentally conscious consumers.

- Material Selection: Prioritize materials known for strength, resistance to wear, and minimal environmental impact, such as organic cotton, recycled polyester, or innovative bio-based fibers.

- Construction Techniques: Utilize strong seams, reinforced stress points, and timeless designs that transcend fleeting fashion trends, ensuring products remain desirable and functional for years.

- Repairability: Design products with easy-to-replace components or provide repair services, extending product life and building customer loyalty.

By focusing on durable and long-lasting designs, businesses can significantly reduce the volume of textiles entering the waste stream. This approach not only benefits the environment but also enhances brand value and customer satisfaction. The initial investment in higher quality materials and design can lead to substantial savings in waste management and raw material procurement over time.

In essence, circular design is about foresight and intentionality. By embedding waste reduction and resource efficiency into the very first stages of product development, US businesses can create a more sustainable and profitable future for their textile operations, directly addressing the pressing challenge of textile waste.

Strategy 2: Implementing Robust Textile Collection and Sorting Systems

Effective textile waste reduction hinges on the ability to efficiently collect and sort discarded materials. For US businesses, establishing or partnering with robust collection and sorting systems is paramount to diverting textiles from landfills and preparing them for reuse or recycling. This strategy involves developing accessible collection points, leveraging technology for sorting, and fostering collaborations across the supply chain.

The challenge lies not just in collecting textiles but in ensuring they are sorted accurately based on fiber composition, quality, and potential end-use. Mixed materials, contamination, and varying quality levels can complicate recycling processes, making precise sorting a critical step. Businesses must invest in the infrastructure and expertise required to manage this complex flow of materials.

Optimizing Collection Points and Logistics

Making it easy for consumers and other businesses to return textiles is a crucial first step. This could involve in-store take-back programs, partnerships with charities, or establishing dedicated collection bins in strategic locations. The logistics of transporting collected textiles to sorting facilities must also be streamlined to minimize carbon footprint and operational costs.

- Retailer Take-Back Programs: Offer incentives for customers to return used clothing to stores, creating a closed-loop system.

- Community Partnerships: Collaborate with local municipalities, non-profits, and educational institutions to set up accessible collection drives and drop-off points.

- Reverse Logistics: Develop efficient transportation networks to move collected textiles from various points to centralized sorting facilities, optimizing routes and reducing fuel consumption.

Once collected, the sorting process requires precision. Manual sorting can be labor-intensive, but technological advancements, such as automated fiber identification systems and optical sorters, are making the process more efficient and accurate. These technologies can differentiate between various fiber types (e.g., cotton, polyester, blends), enabling higher-quality recycling outcomes.

By investing in robust collection and advanced sorting systems, US businesses can significantly increase the volume of textiles diverted from landfills. This not only supports environmental goals but also provides a steady supply of secondary raw materials for recycling and reuse, creating new economic opportunities within the circular economy. This strategic investment is essential for any business serious about meaningful textile waste reduction.

Strategy 3: Investing in Textile Recycling and Upcycling Technologies

Beyond collection and sorting, the actual transformation of discarded textiles into new products is where the circular economy truly takes shape. Investing in advanced textile recycling and upcycling technologies is a cornerstone strategy for US businesses committed to comprehensive textile waste reduction. These technologies enable the regeneration of materials, reducing the reliance on virgin resources and creating high-value products from what was once considered waste.

Textile recycling encompasses various methods, from mechanical processes that shred fabrics into fibers for insulation or new yarns, to chemical recycling that breaks down materials to their molecular level for reconstitution. Upcycling, on the other hand, involves creatively transforming discarded items into products of higher value or quality, often without breaking down the original material structure.

Advancing Mechanical and Chemical Recycling

Mechanical recycling is currently the most widespread method, involving shredding textiles into fibers that can be re-spun into new yarns or used as filling materials. While effective for certain fiber types, it can sometimes degrade fiber quality. Chemical recycling, however, offers a promising solution for mixed textiles and blends, dissolving fibers to extract pure polymers that can be used to create high-quality, virgin-like materials.

- Mechanical Recycling Innovations: Explore new machinery that minimizes fiber damage during shredding, enhancing the quality of recycled fibers for broader applications.

- Chemical Recycling Partnerships: Collaborate with chemical recycling facilities to process complex textile blends, unlocking value from materials previously deemed unrecyclable.

- Infrastructure Development: Support the growth of domestic recycling infrastructure to reduce transportation costs and enhance the efficiency of the recycling pipeline.

Upcycling initiatives, while often smaller in scale, offer unique opportunities for creativity and brand differentiation. Designers can transform pre-consumer waste (e.g., fabric scraps from manufacturing) or post-consumer items into limited-edition collections, accessories, or even furniture. This not only reduces waste but also resonates deeply with consumers seeking unique, sustainable products.

By actively investing in and integrating these recycling and upcycling technologies, US businesses can close the loop on textile materials. This not only dramatically reduces waste but also positions companies as leaders in sustainable innovation, potentially unlocking new revenue streams and strengthening their market presence. Such investments are vital for achieving genuine and scalable textile waste reduction.

Strategy 4: Fostering Consumer Education and Engagement

While businesses bear significant responsibility for textile waste reduction, consumer behavior plays an equally crucial role. Educating and engaging consumers about sustainable practices, product care, and responsible disposal is a powerful strategy for US businesses to amplify their impact. This involves transparent communication, providing clear guidance, and encouraging a shift towards a more conscious consumption mindset.

Many consumers are unaware of the environmental impact of their textile purchases and disposal habits. Bridging this knowledge gap is essential. Businesses can leverage their platforms to inform, inspire, and empower consumers to make more sustainable choices, from how they buy and care for their clothes to how they dispose of them responsibly.

Promoting Sustainable Consumption Habits

Businesses can educate consumers on the benefits of buying durable, high-quality items over fast fashion. This includes highlighting the environmental savings associated with extended product life and encouraging practices like mending, repairing, and swapping clothes. Transparent labeling and product information can guide consumers towards more sustainable choices.

- Care Instructions: Provide clear, easy-to-understand care labels that help consumers extend the life of their garments through proper washing and maintenance.

- Mending and Repair Workshops: Host or sponsor workshops that teach basic repair skills, empowering consumers to fix minor damage instead of discarding items.

- Second-Hand Promotion: Partner with resale platforms or promote the buying and selling of pre-owned items, normalizing and encouraging the circular flow of textiles.

Furthermore, businesses should clearly communicate available options for responsible end-of-life disposal, such as their own take-back programs or local recycling facilities. Simplifying the process for consumers to return or recycle textiles can significantly increase participation rates.

By actively engaging and educating their customer base, US businesses can cultivate a community of environmentally conscious consumers. This not only supports textile waste reduction efforts but also builds brand loyalty and fosters a collective responsibility towards a more sustainable textile ecosystem. Consumer education is a critical component of any successful waste reduction strategy.

Measuring Impact and Financial Benefits

Implementing effective textile waste reduction strategies is not just an environmental imperative; it also offers significant financial benefits for US businesses. Quantifying these impacts is crucial for demonstrating return on investment, securing stakeholder buy-in, and continuously improving sustainability initiatives. This section explores how businesses can measure their progress and realize the economic advantages of their efforts.

The financial gains from waste reduction can manifest in various forms, including reduced waste disposal costs, lower raw material expenses through recycling, enhanced brand reputation, and increased market share among environmentally conscious consumers. A systematic approach to tracking these metrics allows businesses to showcase their commitment and profitability.

Key Performance Indicators for Sustainability

To effectively measure impact, businesses should establish clear Key Performance Indicators (KPIs) related to textile waste. These metrics provide tangible data on progress and identify areas for further improvement. Tracking waste generation, diversion rates, and the financial savings associated with these efforts are essential.

- Waste Diversion Rate: Calculate the percentage of textile waste diverted from landfills through reuse, recycling, or upcycling, providing a clear measure of success.

- Material Cost Savings: Quantify the financial savings achieved by using recycled or upcycled materials instead of virgin resources.

- Disposal Cost Reduction: Track the decrease in waste disposal fees due to reduced landfill reliance.

Beyond direct cost savings, sustainability initiatives can significantly enhance brand value. Consumers are increasingly willing to support companies with strong environmental credentials, leading to increased sales and customer loyalty. This positive brand perception can also attract top talent and facilitate easier access to green financing options.

By diligently measuring their impact and communicating their successes, US businesses can transform textile waste reduction from a cost center into a value driver. The financial benefits, coupled with the positive environmental outcomes, create a compelling case for widespread adoption of these strategies, cementing a more sustainable and profitable future for the industry.

Future Outlook: Policy, Innovation, and Collaboration

The landscape for textile waste reduction in the US is continuously evolving, shaped by emerging policies, technological innovations, and increasing industry collaboration. Looking ahead, US businesses must remain agile and forward-thinking to navigate these changes and capitalize on new opportunities. The future will likely see a greater emphasis on extended producer responsibility (EPR) and the scaling of advanced recycling solutions.

Government policies, particularly at the state and federal levels, are increasingly focused on mandating textile recycling and establishing clear targets for waste reduction. This regulatory push will compel more businesses to adopt sustainable practices, creating a more level playing field and driving systemic change across the industry.

Upcoming Policies and Technological Breakthroughs

Extended Producer Responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, are gaining traction. These policies will likely require brands to fund or manage the collection and recycling of their textiles, incentivizing circular design and material innovation from the outset. Businesses that proactively prepare for these regulations will gain a competitive edge.

- EPR Readiness: Develop internal systems and partnerships to manage end-of-life textiles in anticipation of broader EPR legislation.

- Material Innovation: Invest in research and development of new, fully recyclable or biodegradable textile fibers that reduce environmental impact.

- Digital Tracking: Implement digital product passports or blockchain technology to trace materials throughout the supply chain, enhancing transparency and accountability.

Collaboration among industry stakeholders, including brands, manufacturers, recyclers, and policymakers, will be crucial for scaling solutions. Sharing best practices, pooling resources, and developing common standards can accelerate progress and overcome collective challenges. The transition to a fully circular textile economy requires a concerted effort from all players.

The future of textile waste reduction in the US is bright, albeit challenging. By staying informed about policy developments, embracing technological innovation, and fostering collaborative partnerships, US businesses can not only meet their sustainability goals but also thrive in a rapidly changing market. This proactive stance is essential for driving meaningful and lasting change.

| Strategy | Brief Description |

|---|---|

| Circular Design | Designing products for durability, repairability, and recyclability from the outset to minimize waste. |

| Collection & Sorting | Establishing efficient systems for collecting and accurately sorting discarded textiles for reuse or recycling. |

| Recycling & Upcycling | Investing in technologies to transform textile waste into new materials or higher-value products. |

| Consumer Engagement | Educating and empowering consumers to make sustainable choices in purchasing, care, and disposal. |

Frequently Asked Questions About Textile Waste Reduction

Textile waste reduction is critical for US businesses because it addresses significant environmental issues like landfill burden and resource depletion. Moreover, it offers substantial financial benefits, including reduced disposal costs, lower raw material expenses, and enhanced brand reputation, crucial for attracting environmentally conscious consumers and ensuring long-term sustainability.

Circular design is an approach where textile products are conceived to maximize durability, repairability, and recyclability from the outset. It aims to keep materials in use for as long as possible, moving away from the linear ‘take-make-dispose’ model. This minimizes waste, conserves resources, and integrates end-of-life solutions into the product’s initial design phase.

Businesses can improve textile collection by implementing in-store take-back programs and partnering with local charities or municipalities for drop-off points. For sorting, investing in advanced technologies like automated fiber identification systems is key. Efficient logistics for transportation also play a vital role in diverting textiles from landfills and preparing them for recycling or reuse.

Investing in textile recycling can lead to significant financial impacts, including reduced waste disposal costs and decreased reliance on expensive virgin raw materials. It can also enhance brand reputation, attract new customers seeking sustainable products, and potentially open new revenue streams through the sale of recycled materials or upcycled goods, fostering long-term profitability.

Consumer education is crucial as it empowers individuals to make informed, sustainable choices regarding their textile products. By teaching proper care, repair techniques, and responsible disposal methods, businesses can extend product lifespans and increase participation in recycling programs. This collective effort significantly amplifies waste reduction impacts and fosters a more sustainable consumption culture.

Conclusion

The journey towards comprehensive textile waste reduction for US businesses in 2025 is both a challenge and an immense opportunity. By strategically embracing circular design, establishing robust collection and sorting systems, investing in advanced recycling and upcycling technologies, and actively engaging consumers, companies can transform their environmental footprint while simultaneously realizing substantial financial benefits. The transition away from linear consumption models is not just an ethical choice but a strategic imperative for long-term resilience and profitability in a rapidly evolving market. The future of the textile industry in the US depends on collective action, innovation, and a steadfast commitment to sustainability, ensuring that discarded textiles become valuable resources rather than environmental burdens.