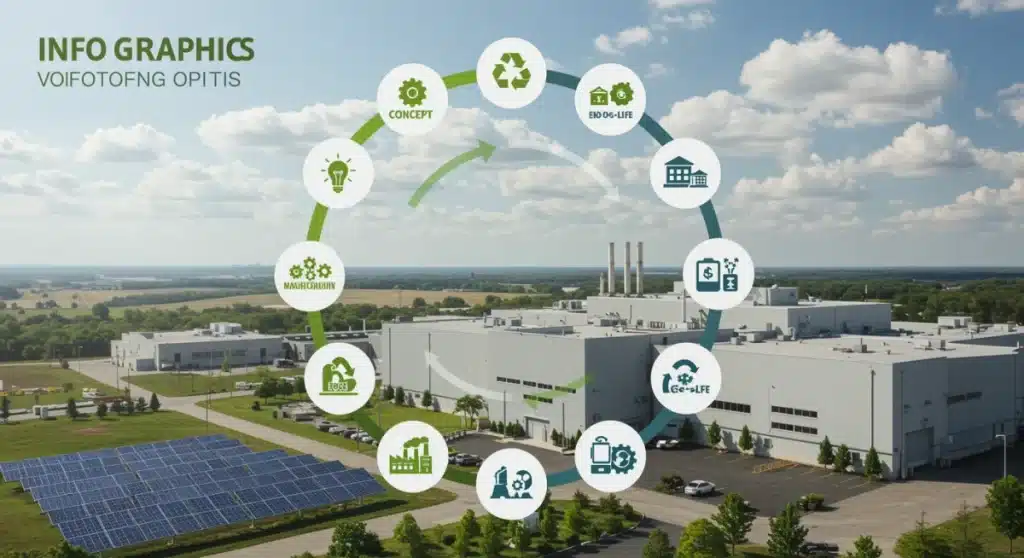

Sustainable Product Lifecycle: 8 Stages in US Manufacturing

Anúncios

Understanding the 8 stages of a sustainable product lifecycle in US manufacturing is essential for businesses aiming to integrate eco-conscious practices, reduce environmental impact, and foster innovation from concept to consumer.

Anúncios

Have you ever wondered about the journey a product takes before it reaches your hands, and its impact afterward? The concept of a sustainable product lifecycle is transforming how US manufacturing operates, moving beyond just production to embrace environmental and social responsibility from start to finish. This comprehensive approach is not merely a trend; it’s a fundamental shift towards a more resilient and eco-conscious industrial future.

The Genesis: Sustainable Concept and Design

The journey of a truly sustainable product begins long before any materials are sourced or machines are turned on. It starts with the initial concept and design phase, where critical decisions are made that will dictate the product’s environmental footprint throughout its entire existence. This stage is paramount for embedding sustainability at the core, not as an afterthought.

Anúncios

In this foundational phase, designers and engineers consider the entire lifecycle, asking crucial questions about material selection, energy efficiency, and end-of-life scenarios. The goal is to minimize negative impacts while maximizing resource efficiency and product utility. This proactive approach can significantly reduce waste and emissions down the line.

Material Selection and Sourcing

Choosing the right materials is perhaps the most impactful decision in sustainable design. It involves a deep dive into the origin, extraction methods, and environmental costs associated with each component. Manufacturers are increasingly prioritizing materials that are:

- Renewable or derived from sustainably managed sources.

- Recycled or contain a high percentage of post-consumer content.

- Non-toxic and safe for both human health and the environment.

- Locally sourced to reduce transportation emissions.

This careful consideration extends to packaging materials as well, aiming for minimal, recyclable, or compostable options. The selection process often involves detailed lifecycle assessments (LCAs) to quantify environmental impacts.

Design for Durability and Disassembly

A sustainable product is built to last, reducing the need for premature replacement and thereby conserving resources. Design for durability focuses on robust construction and high-quality components. Equally important is designing for disassembly, which facilitates repair, reuse, and recycling at the end of the product’s useful life.

This includes using modular components, standardized fasteners, and easily separable materials. Good design anticipates how a product can be taken apart efficiently, ensuring that valuable materials can be recovered and re-entered into the supply chain. This forward-thinking approach creates a foundation for a circular economy.

Ultimately, the sustainable concept and design stage sets the stage for all subsequent phases. By integrating environmental considerations from the very beginning, manufacturers can create products that are not only high-performing but also genuinely responsible and future-proof.

Responsible Material Acquisition and Processing

Once a sustainable design is conceived, the next critical step involves the acquisition and processing of raw materials. This stage focuses on ensuring that materials are obtained and prepared in ways that minimize environmental degradation and uphold ethical labor practices. It’s about translating sustainable design principles into tangible, responsible actions.

The commitment to sustainability here means going beyond simply choosing eco-friendly materials; it involves scrutinizing the entire supply chain. Companies are increasingly demanding transparency from their suppliers, verifying that materials are extracted, harvested, or produced in an environmentally sound and socially equitable manner.

Ethical Sourcing Practices

Ethical sourcing is a cornerstone of responsible material acquisition. This involves ensuring that materials are not linked to deforestation, illegal mining, or human rights abuses. Certifications and third-party audits play a vital role in validating these claims, providing assurance to both manufacturers and consumers.

For example, timber products might carry Forest Stewardship Council (FSC) certification, indicating responsible forest management. Similarly, minerals might be sourced from conflict-free regions, with clear documentation of their origin. This due diligence helps to mitigate risks and build trust across the supply chain.

Minimizing Processing Impacts

The processing of raw materials also presents significant opportunities for sustainability. Energy-intensive processes are being re-evaluated, with a focus on switching to renewable energy sources and optimizing machinery for greater efficiency. Water conservation and waste reduction are also key concerns.

Innovations in processing technology are leading to methods that require less energy, produce fewer emissions, and generate less hazardous waste. For instance, advanced recycling techniques can transform waste materials into high-quality secondary raw materials, closing the loop and reducing reliance on virgin resources. This continuous improvement in processing reduces the overall environmental burden.

The responsible material acquisition and processing stage is about walking the talk. It ensures that the sustainable intentions of the design phase are carried through into the practical realities of obtaining and preparing the components, setting a strong foundation for sustainable manufacturing.

Eco-Efficient Manufacturing and Production

With sustainably sourced materials in hand, the focus shifts to the manufacturing and production phase itself. This stage is where raw materials are transformed into finished products, and it represents a significant opportunity to minimize environmental impact through eco-efficient practices. The goal is to produce goods with the least possible resource consumption and waste generation.

US manufacturers are adopting innovative technologies and operational strategies to make their production lines greener. This includes optimizing energy usage, reducing water consumption, and implementing robust waste management programs. It’s about doing more with less, while maintaining high-quality output.

Energy and Water Conservation

Minimizing energy consumption is a top priority in eco-efficient manufacturing. This involves a multi-faceted approach:

- Investing in energy-efficient machinery and equipment.

- Transitioning to renewable energy sources, such as solar or wind power.

- Optimizing production schedules to reduce idle time and energy waste.

- Implementing smart building management systems to control lighting and HVAC.

Similarly, water conservation is crucial. Manufacturers are installing closed-loop water systems, treating and reusing process water, and implementing low-flow fixtures. These measures significantly reduce the demand on freshwater resources and minimize wastewater discharge.

Waste Reduction and By-product Utilization

Waste reduction is another cornerstone of eco-efficient production. This involves applying the principles of the circular economy directly on the factory floor:

- Implementing lean manufacturing techniques to identify and eliminate waste.

- Recycling or repurposing manufacturing scrap and offcuts.

- Finding new uses for industrial by-products, turning waste into valuable inputs for other industries.

- Minimizing packaging waste within the factory and for outgoing shipments.

Many companies are achieving near-zero waste to landfill, demonstrating that significant reductions are possible with strategic planning and investment. The utilization of by-products not only reduces waste but can also create new revenue streams.

Eco-efficient manufacturing and production are vital for reducing the environmental footprint of products. By focusing on resource optimization and waste minimization, US manufacturers are proving that industrial productivity and environmental stewardship can go hand-in-hand, leading to more sustainable operations.

Sustainable Packaging and Distribution

The journey of a sustainable product doesn’t end on the factory floor; it extends to how it’s packaged and delivered to the consumer. The sustainable packaging and distribution stage focuses on minimizing the environmental impact associated with protecting, transporting, and delivering goods. This phase is crucial for reducing waste and carbon emissions.

Manufacturers are rethinking traditional packaging solutions, moving away from single-use plastics and excessive materials. Simultaneously, logistics are being optimized to ensure products reach their destination efficiently, with the lowest possible environmental cost. It’s a holistic approach to getting products to market responsibly.

Innovative Packaging Solutions

Sustainable packaging aims to achieve its protective function with minimal environmental impact. Key considerations include:

- Using recycled, recyclable, or compostable materials.

- Reducing the overall amount of packaging material.

- Designing packaging for reuse or multiple uses.

- Eliminating unnecessary void fillers and plastic wraps.

Many companies are experimenting with innovative materials like mushroom-based packaging, seaweed films, and plant-based bioplastics. The goal is to create packaging that is functional, protective, and seamlessly integrates into a circular economy, minimizing its footprint from creation to disposal.

Optimized Logistics and Transportation

Distribution is often a significant contributor to a product’s carbon footprint. Sustainable distribution strategies focus on:

- Optimizing shipping routes to reduce fuel consumption.

- Utilizing more fuel-efficient transportation methods, such as rail or sea freight over air freight.

- Consolidating shipments to maximize cargo capacity.

- Investing in electric or hybrid delivery vehicles for last-mile logistics.

Some companies are also exploring localized manufacturing and distribution hubs to shorten supply chains and reduce transportation distances. The aim is to deliver products efficiently while minimizing greenhouse gas emissions associated with their movement.

By focusing on sustainable packaging and optimized distribution, companies can significantly reduce their environmental footprint during this critical phase. It demonstrates a commitment to sustainability that extends beyond the product itself, encompassing its entire journey to the consumer.

Sustainable Product Use and Consumer Engagement

Once a product reaches the consumer, its sustainability journey continues through the use phase. This stage focuses on minimizing the environmental impact of the product during its active life, and crucially, on engaging consumers to participate in sustainable practices. A truly sustainable product is designed not only to be eco-friendly in its creation but also in its daily operation and maintenance.

Manufacturers play a key role in empowering consumers to use products more sustainably. This involves clear communication, product design features, and support mechanisms that encourage responsible consumption and extend product lifespan. It’s a collaborative effort between producer and user.

Designing for Efficiency and Longevity

Products designed for sustainable use prioritize energy and resource efficiency. This means creating appliances that consume less electricity or water, vehicles with better fuel economy, and electronics that require less power. Longevity is also critical; a durable product that lasts longer reduces the need for frequent replacements, thus conserving resources and preventing waste.

Manufacturers can integrate features that promote sustainability, such as:

- Modular designs that allow for easy repair and replacement of components.

- Software updates that extend the functional life of electronic devices.

- Clear instructions for proper maintenance and care.

By building products that are inherently efficient and long-lasting, companies empower consumers to make sustainable choices simply by using the product as intended.

Educating and Engaging Consumers

Consumer behavior has a significant impact on a product’s overall sustainability. Manufacturers can influence this through effective education and engagement strategies:

- Providing clear labels and certifications that highlight eco-friendly features.

- Offering tips and guides on how to use and maintain products efficiently.

- Creating programs for product take-back, repair, or upgrade.

- Promoting responsible disposal information for end-of-life.

Brands that transparently communicate their sustainability efforts and provide tools for consumers to act responsibly foster a deeper connection and shared commitment to environmental stewardship. This engagement transforms consumers into active participants in the sustainable lifecycle.

The sustainable product use and consumer engagement stage highlights that sustainability is a shared responsibility. By designing for efficiency and actively engaging consumers, manufacturers can extend the positive impact of their products far beyond the point of sale, contributing to a more sustainable consumption pattern.

End-of-Life Management: Reuse, Repair, and Recycling

The final, yet immensely crucial, stage of a sustainable product lifecycle is its end-of-life management. This phase moves beyond traditional disposal methods, focusing instead on strategies that keep products and materials in circulation for as long as possible. The emphasis is on reuse, repair, and recycling, embodying the principles of a circular economy and minimizing waste sent to landfills.

Effective end-of-life management requires foresight during the design phase and robust infrastructure for collection and processing. It’s about seeing discarded products not as waste, but as valuable resources waiting to be transformed.

Promoting Reuse and Repair

Before considering recycling, the most sustainable options for a product nearing its end-of-life are reuse and repair. Manufacturers can facilitate these options by:

- Designing products that are easy to repair, with readily available spare parts and repair manuals.

- Offering repair services or partnering with third-party repair networks.

- Developing take-back programs for products that can be refurbished and resold.

- Supporting marketplaces for second-hand goods, extending product utility.

The growing repair economy not only reduces waste but also creates jobs and fosters a more resilient, less consumption-driven society. Encouraging consumers to repair rather than replace is a powerful sustainability lever.

Advanced Recycling and Material Recovery

When a product can no longer be reused or repaired, recycling becomes the next best option. This involves breaking down the product into its constituent materials, which can then be used to create new products. Advanced recycling technologies are making it possible to recover a wider range of materials, including complex plastics and composites.

Key aspects of effective recycling programs include:

- Establishing accessible collection points and take-back schemes for consumers.

- Investing in sorting and processing infrastructure to efficiently separate materials.

- Developing markets for recycled materials to ensure they are re-integrated into manufacturing.

- Innovating in chemical recycling to process plastics that are difficult to mechanically recycle.

The success of end-of-life management hinges on collaboration between manufacturers, consumers, recyclers, and policymakers. By prioritizing reuse, repair, and advanced recycling, the US manufacturing sector can significantly reduce its environmental impact and move closer to a truly circular economy, where resources are valued and waste is minimized.

Continuous Improvement and Feedback Loops

A truly sustainable product lifecycle isn’t a static process; it’s a dynamic and evolving system that relies on continuous improvement and robust feedback loops. This stage emphasizes the importance of ongoing monitoring, evaluation, and adaptation across all previous stages to enhance environmental performance and efficiency over time. It’s about learning, innovating, and constantly striving for better outcomes.

Manufacturers committed to sustainability understand that the journey is iterative. They actively seek data, gather insights, and engage with stakeholders to identify areas for improvement, ensuring their products and processes remain at the forefront of eco-conscious practices.

Lifecycle Assessment (LCA) and Performance Metrics

Central to continuous improvement is the regular conduct of Lifecycle Assessments (LCAs). An LCA systematically evaluates the environmental impacts of a product throughout its entire life, from raw material extraction to disposal. This data provides a comprehensive understanding of hotspots where environmental impact is highest, guiding targeted improvement efforts.

Beyond LCAs, companies track various performance metrics, such as:

- Energy and water consumption per unit of production.

- Waste generation rates and diversion from landfill.

- Carbon emissions across the supply chain.

- Percentage of recycled content in products.

These metrics serve as benchmarks, allowing manufacturers to measure progress, set new goals, and demonstrate their commitment to sustainability with verifiable data.

Stakeholder Engagement and Innovation

Feedback loops are not just internal; they extend to all stakeholders, including suppliers, customers, and even competitors. Engaging with these groups provides invaluable insights and drives innovation.

- Supplier Collaboration: Working with suppliers to develop more sustainable materials and processes.

- Customer Feedback: Listening to consumer preferences and concerns regarding product sustainability.

- Industry Partnerships: Collaborating with other companies and research institutions to share best practices and develop new sustainable technologies.

- Regulatory Compliance: Staying abreast of evolving environmental regulations and proactively adapting practices.

This open dialogue and collaborative spirit foster a culture of continuous innovation, leading to breakthroughs in material science, manufacturing processes, and end-of-life solutions. The commitment to continuous improvement ensures that the sustainable product lifecycle remains dynamic, responsive, and increasingly effective in minimizing environmental impact.

The Role of Policy and Regulations in US Manufacturing

While industry initiatives are crucial, the broader framework of policy and regulations plays an indispensable role in shaping and accelerating the adoption of sustainable practices within US manufacturing. Government mandates, incentives, and standards provide both the necessary guardrails and the impetus for businesses to integrate environmental responsibility more deeply into their operations. This external pressure and support are vital for systemic change.

Policies can level the playing field, ensuring that sustainable choices are not just optional but become standard practice across sectors. They also drive innovation by setting ambitious targets and rewarding eco-friendly advancements.

Driving Compliance and Setting Standards

Environmental regulations, such as those related to air and water quality, hazardous waste management, and chemical use, directly influence manufacturing processes. Compliance with these rules ensures a baseline level of environmental protection. Furthermore, specific product standards can mandate energy efficiency, material content, or end-of-life requirements, pushing manufacturers towards greener designs.

Examples include:

- EPA regulations on emissions and waste disposal.

- State-level extended producer responsibility (EPR) laws for certain products like electronics or packaging.

- Energy Star ratings for appliances, encouraging energy-efficient designs.

- California’s strict chemical regulations, influencing product formulations nationwide.

These policies prevent environmental harm and establish a common understanding of what constitutes responsible manufacturing.

Incentives for Sustainable Innovation

Beyond compliance, governments often provide incentives to encourage manufacturers to go above and beyond minimum requirements. These can include:

- Tax credits for investments in renewable energy or energy-efficient equipment.

- Grants for research and development of sustainable technologies and materials.

- Subsidies for adopting circular economy practices, such as waste reduction or material reuse.

- Procurement policies that favor products with stronger environmental credentials.

Such incentives reduce the financial burden of transitioning to more sustainable models, making it more attractive for businesses to innovate and invest in greener practices. They demonstrate a recognition that sustainability is not just an environmental imperative but also an economic opportunity, fostering a competitive advantage for eco-conscious businesses.

The role of policy and regulations is to create an enabling environment where sustainable product lifecycles can flourish. By balancing strict requirements with supportive incentives, policymakers can effectively guide US manufacturing towards a more environmentally responsible and economically vibrant future.

The Economic and Social Benefits of Sustainable Practices

Embracing a sustainable product lifecycle extends far beyond environmental stewardship; it unlocks a myriad of economic and social benefits for US manufacturing companies and society at large. This stage highlights that sustainability is not just a cost center but a strategic investment that yields significant returns, fostering resilience, innovation, and positive societal impact. It demonstrates that doing good can also mean doing well.

Companies that integrate sustainability into their core operations often find themselves more competitive, attractive to talent, and better positioned for future growth in an increasingly eco-conscious market.

Enhanced Brand Reputation and Market Competitiveness

In today’s market, consumers are increasingly prioritizing sustainable products and brands. Companies recognized for their commitment to sustainability often experience:

- Improved brand reputation and customer loyalty.

- Access to new markets and consumer segments.

- Increased sales and market share.

- Differentiation from competitors who lag in sustainability efforts.

A strong sustainability narrative can be a powerful marketing tool, resonating with environmentally conscious buyers and investors. It builds trust and demonstrates a forward-thinking approach to business.

Cost Savings and Operational Efficiency

Implementing sustainable practices frequently leads to tangible cost reductions and improved operational efficiency. This includes:

- Lower energy bills through efficiency upgrades and renewable energy adoption.

- Reduced raw material costs by using recycled content and minimizing waste.

- Decreased waste disposal fees due to effective recycling and reuse programs.

- More efficient use of water and other resources, leading to savings.

These operational savings directly impact the bottom line, proving that sustainability can be a driver of financial performance. The initial investment in green technologies often pays for itself through long-term savings.

Social Impact and Employee Engagement

Sustainable manufacturing also has profound social benefits. It contributes to:

- Improved worker safety and health through reduced exposure to hazardous materials.

- Creation of green jobs in areas like renewable energy, recycling, and sustainable design.

- Stronger community relations through responsible environmental practices.

- Enhanced employee morale and retention, as workers are proud to be part of a purpose-driven company.

By fostering a positive social impact, companies strengthen their social license to operate and become more attractive employers, drawing in talent passionate about making a difference. The economic and social benefits underscore that sustainability is a win-win strategy, creating value for businesses, communities, and the planet.

| Stage | Key Focus |

|---|---|

| Concept & Design | Embedding sustainability from the start, material selection, design for disassembly. |

| Material Acquisition | Ethical sourcing, minimizing processing impacts, supply chain transparency. |

| Manufacturing | Eco-efficiency, energy/water conservation, waste reduction, by-product utilization. |

| End-of-Life | Reuse, repair, advanced recycling, material recovery. |

Frequently Asked Questions About Sustainable Product Lifecycles

It’s a holistic approach to product development that considers environmental and social impacts from raw material extraction, through manufacturing, use, and end-of-life. The goal is to minimize negative impacts and maximize resource efficiency across all stages, fostering a circular economy.

Sustainable design is crucial because decisions made at the concept stage determine up to 80% of a product’s environmental impact. It allows for the proactive selection of eco-friendly materials, designs for durability, and ease of recycling, preventing problems later in the lifecycle.

US manufacturers achieve eco-efficient production by investing in energy-efficient machinery, utilizing renewable energy, optimizing water usage, and implementing lean manufacturing techniques to minimize waste. They also focus on recycling by-products and reducing overall resource consumption.

Consumers play a vital role by choosing sustainable products, using them efficiently, maintaining them properly, and participating in repair or recycling programs. Their purchasing decisions and post-purchase behaviors significantly influence the overall environmental footprint of products.

Businesses benefit from enhanced brand reputation, increased market competitiveness, significant cost savings through resource efficiency, and improved operational performance. Additionally, it fosters stronger community relations and boosts employee engagement, contributing to long-term resilience and growth.

Conclusion

The journey from concept to consumer, guided by the principles of a sustainable product lifecycle, represents a transformative shift in US manufacturing. By diligently navigating the eight stages—from initial sustainable design and responsible material acquisition to eco-efficient production, smart distribution, mindful consumer use, effective end-of-life management, continuous improvement, and supported by robust policies—companies are not only reducing their environmental footprint but also unlocking significant economic and social advantages. This comprehensive approach ensures that products are not only functional and desirable but also contribute positively to a healthier planet and a more resilient economy for generations to come.